In this Article, we’ll dive into home snowmaking science.

We’ll explore several topics:

- How snowflakes form in nature

- How snow guns work

- Differences between commercial and residential snowmaking systems

- The role of misting nozzles

- What a nucleator does in a snow gun

- How different home snow gun design’s function

- A detailed look at Backyard Snowstorm’s unique snow gun design

Snow Creation in Nature

In the atmosphere there are small, microscopic dust particles floating around. The same thing with water droplets but in the form of humidity. Under the proper conditions those water droplets will collide with a microscopic dust particle -and when the temperature and humidity are low enough that water droplet- will freeze into a very small Ice Crystal. Continuing with that Ice Crystal that’s formed, it will start to collide with other water droplets that are up in the atmosphere. Once those other water droplets collide with that Ice Crystal, they will attach and freeze onto that Ice Crystal (or the nucleus). Once they attach onto the nucleus, they’ll Orient themselves according to the molecular structure of the Ice Crystal. As they gain Mass it’ll start to fall, as it attaches to those other water droplets it will continue to build and other water droplets will freeze onto the nucleus. As it falls towards the ground that is what creates what we know as a “snowflake”. Every snowflake is different, but they’re all oriented according to the molecular structure of the Ice Crystal.

Snow Gun Replication

Snow guns and snow making systems replicate that same process on the ground using equipment. Such as pumps, water reservoirs, nozzles, nucleation sites etc. All of that replicates the same process but in a different way.

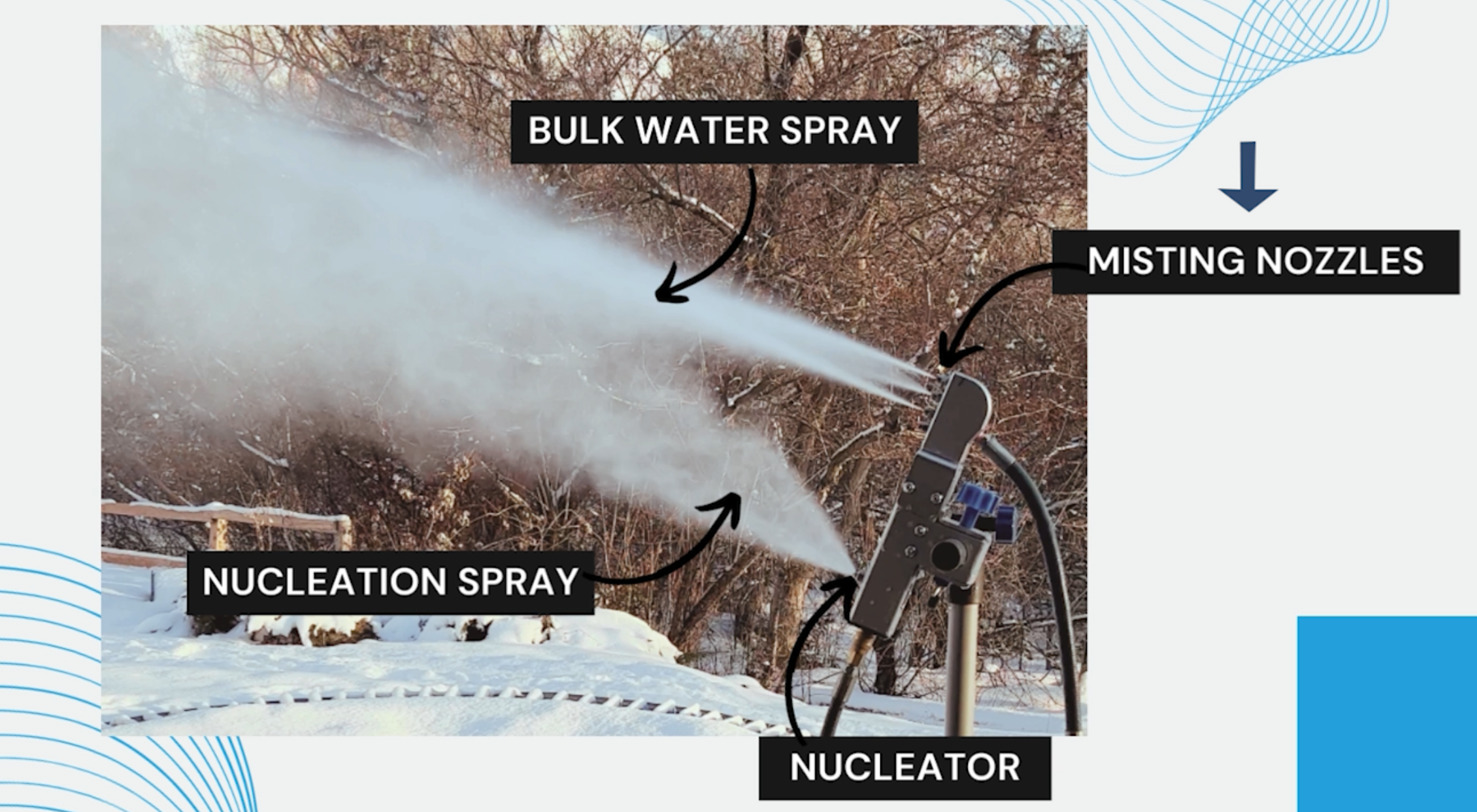

There are two main parts of any snow gun. There’s the snow gun misting nozzles and there’s a nucleator misting nozzle.

The snow gun misting nozzles produce the bulk water spray. We can think of these misting nozzles as the water that would be occurring naturally in the atmosphere in the form of humidity. It’s those water droplets that are up in the atmosphere, but we use pressurized water that we push through nozzles in order to create it on the ground. The bulk water spray still needs a “nucleation site”.

In nature we have dust particles that can act as a nucleation site for water droplets to freeze onto. In a snow gun we need to create those nucleation sites. A nucleator is a combination of fittings that project microscopic ice crystals into the bulk water spray. These small ice crystals that are produced in the nucleator will act as nucleation sites for the bulk water spray. So, the same process that would happen in nature happens much closer to the ground and happens a lot quicker. We just use different equipment to perform the same snowflake formation process.

Commercial vs. Residential Snowmaking

There are a lot of differences between Commercial Snowmaking and Residential Snowmaking. The main one is going to be water flow or snow output.

Water Flow

With commercial systems, typically they’re going to be somewhere between 30 to 100 gallons per minute (GPM) of water flow per snow gun. That’s a lot of water moving through that snow gun, due to the need that these Resorts have for making high quantity of snow. Residentially, we are limited by the equipment, by power available at your home, and by the amount of water that a home can output. Typically, these systems are 1 to 12 gallons per minute (GPM). That’s about 10 times as small as a commercial snowmaking setup.

Cost

Commercial systems can cost millions of dollars. There’s a lot of pumps, large equipment, water sheds, reservoirs, and a lot of time invested in order to get the water pumped throughout the mountain. A lot more money involved in a commercial set up than residential. As we know we use household equipment; pressure washers, air compressors, garden spikets, and house hoses in order to accomplish the same tasks.

These are the main differences, there’s a lot more differences in designs; commercial has more features typically more adjustment than you can have in residential snow guns.

Misting Nozzles

Misting nozzles provide how the bulk water spray will exit the snow gun. The nozzles are important to shear water into the proper size. As water enters the snow gun, we’re going to fasten certain nozzles into the head of the snow gun that are matched to the flow rate of the pressure washer. With a typical household pressure washer, it’s going to be a “positive displacement pump” which means that it can output a certain GPM (gallons per minute) and it can go up to a max pressure. It’s just going to keep pumping that water at a fixed rate, and when we put those nozzles in the head, we’re putting the nozzles to create an overall pressure in the snow gun. When we get to that pressure then it’s going to produce a certain size water droplet that will be anywhere from 500 – 1500 microns in diameter. The size of the water droplet will depend on the amount and of nozzles, and the combination of those two with the flow rate of the pressure washer. 500-1500 microns is the typical size that you’re going to see with a home snow maker and with commercial snowmakers. These water droplet sizes are the correct sizes of water droplet that when it collides with a dust particle (nature) or a nucleation site (Home Snow gun) and under those proper weather conditions it’s going to be able to freeze and continue to make snowflakes.

These are crucial for producing the correct water droplet size (500-1500 microns) for freezing. The size depends on the number and size of nozzles used with the pressure washer’s flow rate.

Nucleator

The nucleator is going to create small ice crystals as “nucleation sites” for the bulk water spray. The nucleator will use a combination of air and water to do that. So, compressed air and smaller amounts of water will mix in a nozzle or a series of nozzles and will shear the water droplets into very small ice crystals. they’re going to be 30 to 70 microns in diameter and it will freeze very quickly as it exits the nozzle and those ice crystals as they are projected into the bulk water spray will freeze onto the ice crystals.

Home Snow Gun Designs

There are two main designs: external and internal nucleation.

- External Nucleation: If you look at this picture above you can see that there’s four nozzles. Up top, those are the misting nozzles and then that bottom nozzle is actually two nozzles, one of them is going to be an air nozzle that is fastened that’s projecting air straight out from the snow gun and the other nozzle that’s going straight up is a water nozzle. The water nozzle is shooting a small stream of water. These air and water streams mix outside of the snow gun. The air and water as they mix, the compressed air will break those water droplets down into small ice crystals for nucleation. So, the first style that you’ll see is the external style.

- Internal Nucleation: internal style nucleus we can see the top three nozzles on this design above are the misting nozzles that are the bulk water spray. Then that bottom nozzle is the nucleation spray. That bottom nozzle is going to be a combination of air and water that is mixing inside of the piping before it exits the nucleation nozzle. The air and water will shear those water droplets inside of the piping before it exits the nozzle. Then it’s projected out into the main bulk water spray.

Both Styles have their pros and cons. The first thing is with an internal style nucleation design there’s a lot of risk of water backflow. When you turn on your pressure washer you have a valve, the valve hopefully is shut but if it’s not then you turn that pressure washer on water can backflow into the airline. And when its backflows into the airline it can actually, go all the way back into the air compressor itself and it will damage the air compressor. Same thing for the air if you don’t turn on the water and you turn on the air it can back flow the other way. So, there’s a few different ways that back flow can happen.

With the external style nucleation, you don’t have that risk of back flow since the water and air mix outside of the snow gun itself it’s not going to backflow. As far as efficiency goes the internal style nucleation designs have more efficient mixing since the water and air is mixed inside of that nozzle and it shears a little bit more evenly. It’s more of an even distribution of ice crystals that are being projected. With the external style, the water and air as they mix outside of the gun have a lot of energy that is lost before those streams mix. There’s a little bit of less efficiency in mixing and it can be a larger distribution of small water droplet sizes. Operationally, the external is a lot easier to operate. Typically, because you can turn on the system and walk away and there’s not really any risk of things not working out since the air nozzle and the water nozzle in that are fixed. It’s a set orifice size you turn both air and the water on you and don’t must adjust anything.

Backyard Snowstorm Nucleation Design

We have used both the External and Internal designs. We use a commercial style nucleation nozzle that’s been customized to our snow gun itself. In the diagram above you can see a breakdown of the different compound components. We have a fitting that air and water pass through, they don’t mix until this top chamber, and that reduces any water back flow issues. Water will go into one side and air will go into the other. In that fitting right above the main rectangular body these two streams (air and water) are separated but they are mixed into the same plane. Now they’re both traveling upwards the water will exit that small spire and the air will exit on both sides of that spire then mix in that external chamber. This nozzle is commercial grade and found on commercial snow guns. It has superior mixing, due to the external chambers the water in there is mixing in that chamber but it’s not inside of the piping like a true internally mixed snow gun. The external chamber is customized, and it matches the spray pattern of the bulk water spray. In this picture above you can see on the top is the bulk water spray and it’s spraying at a 65° angle. The bottom nucleation spray is designed to match that and it’s spraying at 55° so that the water can be nucleated. From the side profile you can also see that we have the nucleation spray coming out almost parallel to the main bulk water spray and up at a 30° angle.

Share:

How do Nucleation Nozzles Work in Snowmaking?

How Much Does It Cost to Run a Home Snowmaking System?